Wechat public account

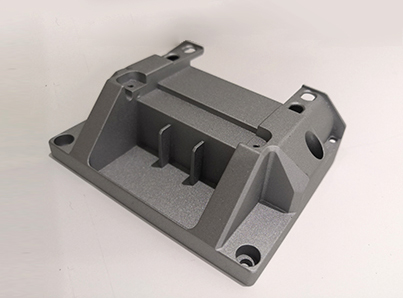

The production processof a semi-solid magnesium die casting plant is a complex and delicate process, which involves multiple links and process steps, aiming at producing high-quality and high-precision magnesium alloy die casting parts.The following is aHuzhou Rui magnesium precision metalDetailed analysis of the production process of semi-solid magnesium die casting plant:

1. Material preparation and pretreatment

Select materials: The selection of high purity magnesium alloy material to ensure that the quality and performance of the material meet the production requirements.

preconditioning: Pretreatment of magnesium alloy materials, such as cleaning, peeling, etc., to improve the surface quality of materials and die casting effect.

2. melting and semi-solid processing

Smelting: Preheat the melting furnace and melting tools, add high purity magnesium ingot or magnesium alloy material, and heat to the molten state under the condition of protection gas. In the melting process, the temperature and melting time need to be strictly controlled to ensure the uniformity and stability of the alloy material.

Semi-solid processingBy adjusting the temperature and cooling rate, the molten magnesium alloy material enters a semi-solid state. This state of the material has good rheological properties and die-casting properties, providing favorable conditions for subsequent die-casting molding.

3.Die casting

Mold preparation: Design and manufacture die-casting molds according to product requirements to ensure mold accuracy and durability.

Die casting: The semi-solid magnesium alloy material is injected into the injection chamber of the die casting machine, and the material is filled into the mold cavity through high pressure injection molding technology. In the process of die casting, it is necessary to strictly control the parameters of the pressure, temperature and injection speed of the die casting machine to ensure the quality and accuracy of the product.

4.Post-processing and inspection

Demoulding and cleaning: After the die casting has cooled, remove it from the mold and clean it to remove excess burrs and residue.

Heat treatmentHeat treatment of die castings to improve their mechanical properties and corrosion resistance. It is necessary to control the heating temperature and time during the heat treatment process to ensure the uniformity and stability of the heat treatment.

Inspection and testing: Quality inspection and performance testing of die-casting parts, including appearance inspection, dimensional measurement, mechanical property testing, etc., to ensure that products meet customer requirements and industry standards.

5.Packaging and delivery

Qualified die castings will be packaged to protect the safety of the product during transportation and storage. Finally, the product is shipped to the designated location as required by the customer.

To sum up,Semi-solid magnesium die casting plantis a complex process involving many links and process steps. By strictly controlling the parameters and quality requirements of each link, high quality and high precision magnesium alloy die casting can be produced.